The case for pushback racking as an investment for effective high-density storage

High-density pushback systems are designed to attain up to 100% more storage than standard pallet racking, and equal or greater increases over poorly occupied drive-in or floor storage layouts. While many people are discouraged from buying pushback racks because of the perceived high cost ($100-$200 per pallet depending on the application – see the bottom of this page for more detail), those who examine all of the aspects of operating a warehouse know that pushback racking is easily justified.

High density storage candidate

Drive-in honeycombing – wasted space

The true cost of pushback racking per pallet stored includes all elements within the warehouse:

Capital Costs

- land

- buildings

- mobile handling equipment (forklifts)

- storage systems (racking)

Operating Costs

- labour

- transportation

- maintenance/insurance/taxes

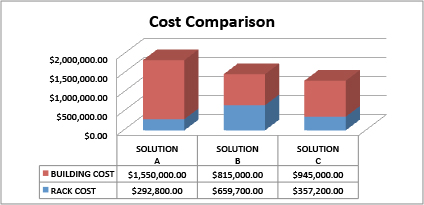

The following simple examples (solutions A, B, and C) are three designs that compare the cost of three racking layouts. The solutions just look at the cost of building and racking, no allowances have been made for operating costs or forklifts. Comparison of these examples shows that similar volumes can be stored in smaller warehousing space when pushback racking is used.

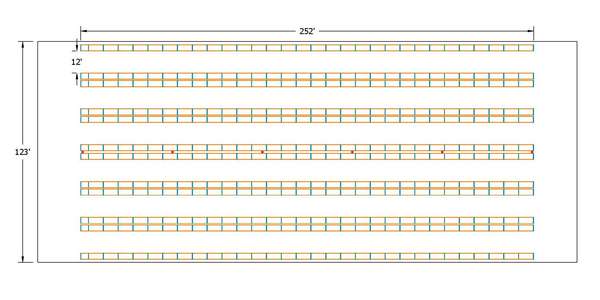

Solution A – All standard selective rack

- Standard Selective Rack

- 2,928 Pallets, 31,000 square feet

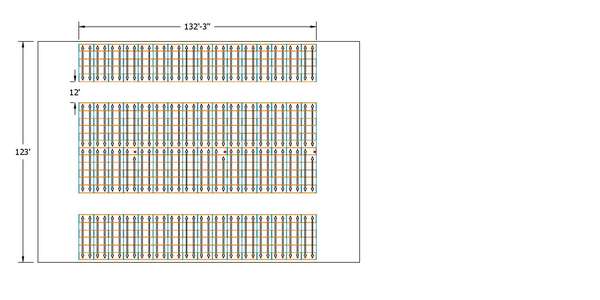

Solution B – All pushback and resizing the building to hold the same number of pallets as solution A

- 5 and 6 Deep Pushback

- 2,932 Pallets, 16,300 square feet

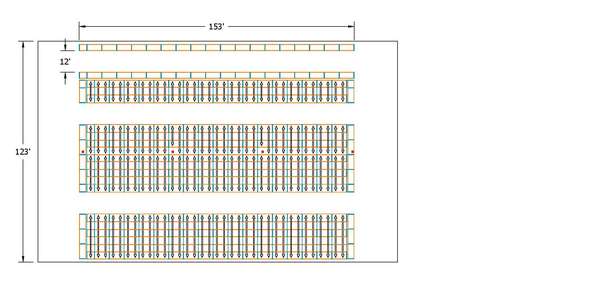

Solution C – A mix of standard selective rack, pushback and floor storage, where the building size has been adjusted to hold the same number of pallets as solution A

- Standard Selective Rack, 3, 4, 5 & 6 Deep Pushback above floor Storage

- 2,944 Pallets, 18,900 square feet

The chart below shows the total cost of each solution when building costs are included with the rack costs. While operational costs have not been included, it stands to reason that a smaller facility will incur lower heat, lighting, maintenance and insurance costs. As well, because the forklifts will travel shorter distances in a smaller building, fewer forklifts will be required.

| Solution A | Solution B | Solution C | |

| Rack Cost | $292,800.00 | $659,700.00 | $357,200.00 |

| Building Cost | $1,550,000.00 | $815,000.00 | $945,000.00 |

Interested in learning more about Pushback Racking? Please read our educational articles and our Pushback Racking FAQ. Or contact our team if you have any specific questions or inquiries.

Pushback Rack Pricing

Pricing for pushback will vary by lane depth, pallet weight, rack height and configuration. 2 deep pushback is less expensive that 4 deep pushback because deeper lanes require more carts and steel.

Typically pushback racking ranges between $100-$200 per pallet, but in some cases works out to less than that. In the photo below we see a very popular configuration showing floor storage with pushback up above. In this particular case the first pushback level is also double stacked pallets.

This layout works out cheaper than a similar drive-in layout (around $80 in this case) and yet provides more flexibility and faster load/unload cycles. Inventory analysis and building layout will help decide on a design that will be most cost effective. Contact 3D today to receive more detailed information.