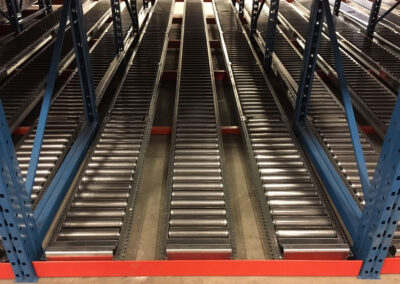

Strength and versatility with steel rollers for pallet flow

Steel rollers in pallet flow rack systems ensure stability while providing a large load bearing capacity and support for special pallets, steel containers or plastic totes.

While generally more expensive than other flowrack systems, rollers typically provide the most flexibility for different pallet styles. The automotive industry is a large user of roller-based systems for these reasons. While rollers come in a multitude of sizes and styles, there are two types that are most commonly used: 1.9” diameter and 2.5” diameter. These can be provided with either a galvanized or unfinished surface.

Steel rollers in pallet flow rack systems ensure stability while providing a large load bearing capacity and support for special pallets, steel containers or plastic totes.

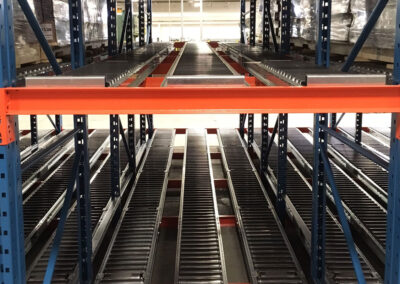

1.9” Diameter Rollers

These rollers are generally used with lighter pallets or with formed pallets with “pods”. They are normally provided with 16-gauge wall thickness; however, heavier wall versions are often used at the load end of these lanes to give a greater resistance to impact damage. Maximum load rating is 250 pounds per roller.

2.5” Diameter Rollers

These rollers would be used for heavier loads, longer rollers, and flowrack systems where increased “rollability” is required. Standard version rollers have a 12-gauge wall thickness with a load rating of 280 pounds per roller. A heavy-duty roller with a 10 or 8 gauge wall thickness and a welded structural steel frame can provide a 500 pound roller rating.

Speed Controllers

3D offers both full width brake rollers and underslung indirect brakes for our pallet flow rack systems depending on the application.

Contact Us

Discover the durability of our steel rollers – contact us for more information.