We are often asked “When should I use a skate wheel conveyor for my flowrack system versus polycarbonate wheels or rollers?” While there are many different opinions in the industry as to the answer to this question, with over 25 years of manufacturing and configuring all types of gravity flowrack, here are our thoughts on the topic.

Skate Wheel Conveyors are Best Suited to Picking Systems

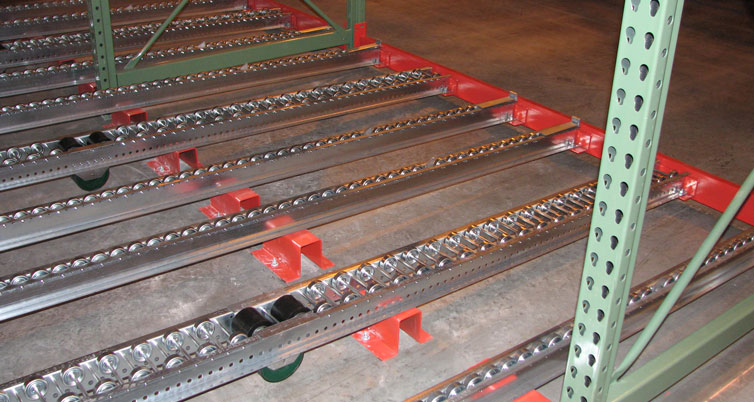

The main benefit of a skate wheel conveyor is their low cost. The 1.9” diameter steel wheels are manufactured by the millions and because of the simple construction and a stamped manufacturing process they are very inexpensive when compared to polycarbonate wheels or rollers. This simplicity does come with some drawbacks however. Skate wheels are narrow (typically about ½” wide), have a non-precision bearing and have a smaller diameter than polycarbonate wheels or rollers – these factors result in less support on the pallet surface as well as less “rollability”. It is not uncommon in a typical 2 track system installed at a slope of 3/8” per foot that a pallet will not start to roll on its own without a push.

Think 2, 3 and maybe 4 pallets deep when using a Skate Wheel Conveyor

Due to the factors cited above, we believe that skate wheel conveyor lanes should be short in length and generally accessible to the operators so that they can give a small push or pull to move the pallets forward. This means that the best applications are bottom level picking systems or they may be used in a multi-level pick module. Most of these applications do not use speed controllers to maintain a safe travel speed – that’s why we think 2 and 3 deep systems make the most sense. With lighter pallets that are stretched wrapped and uniformly stable 4 deep may be workable.

Skate Wheel Conveyor Rails are not suited to deep lane Pallet Flow

For some people, the appeal of a low cost skate wheel conveyor generates requests for deep lane pallet flow using these components. While there are a small number of instances where a 3 track configuration of skate wheels utilizing speed controllers can be used (good pallets/loads under 1000 pounds, 4-10 pallets deep), we highly recommend a polycarbonate wheel system for deep lane pallet flow. Polycarbonate wheels have a larger diameter (2.88”), a wider surface (1” versus 0.5”) and better quality bearings – all resulting in a substantially more reliable flow. Using a skate wheel conveyor in a deep lane could result in hang ups that are difficult to access and resolve.

Contact 3D to discuss your Skate Wheel Conveyor requirements

At 3D we have an experienced team of flowrack designers who can look at your application, your pallets and loads to suggest the best components for your system. Whether that’s a skate wheel conveyor, polycarbonate wheels or rollers, we have what you need for a successful pallet flowrack module.