Selecting the right high-density warehouse solution begins with an in-depth inventory analysis.

At 3D Storage Systems we are happy to provide free inventory analysis services to ensure your organization selects the most cost-effective and advantageous storage solution that will grow along with your company and its shipping requirements.

We initiate the inventory analysis process by asking a number of straightforward questions

This helps us determine which solution is the right one for you, some of which include:

- What are your average inventory turns annually by product?

- What is the estimated percentage of fully loaded pallets that arrive at your warehouse?

- What percentage of them are shipped out full?

- Do you receive and ship half-full pallets? If so, how many on a daily, weekly, and monthly basis?

- How many overall orders does your company receive daily, weekly, and monthly?

- What does an average order consist of? What do all orders for a typical day consist of?

- Does your business experience seasonal increases and decreases?

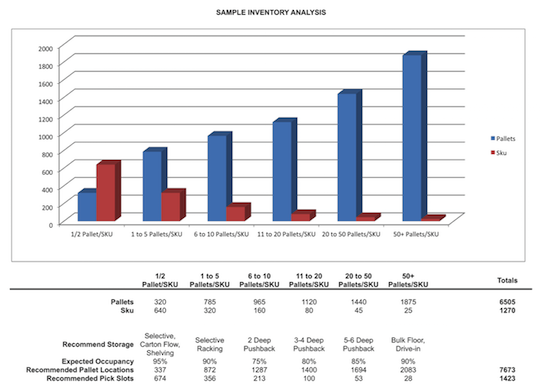

Sample Inventory Analysis Report

Determining the right warehouse layout and storage system for your business is dependent upon a multitude of factors.

It begins with a thorough, in-depth inventory analysis & inventory analysis report of the products that need to be stored, and then forecasting the appropriate level of support for your company’s operations over the short-, mid-, and long-term.

Do you need a sturdy, pallet racking system with multiple faces that conserves warehouse space and adequately houses a high volume of pallets?

The answer to all of these questions can be answered with a inventory analysis report from 3D Storage Systems! You may require pushback racking, Or if your organization manufactures high volumes of product a pallet flow solution may be the better option. If establishing picking and packing efficiencies and maintaining a First-In, First-Out (FIFO) system for case quantities is top-of-mind, a carton flow system may be the way to go.

Once we have all the storage-related data compiled and analyzed, we then match your inventory flows to the best storage solution. Most often two or more types of storage systems are required to provide density, selectivity and flexibility.

Have questions about our inventory analysis services?

Contact us and let’s get to work finding the most cost-effective, high quality, and productive storage solution for your warehouse operations.