Achieve FIFO storage with 3D Storage Systems’ Dynamic Pushback Racking! It can easily be configured to properly achieve FIFO (First-In-First-Out).

Are You Interested In Pushback Racking Systems?

FIFO is an acronym that stands for “First In First Out”. As it applies to warehouse and distribution facilities, “FIFO System” means ensuring that the oldest pallets and products are shipped before the newer ones, thus properly rotating the stock. Most often a FIFO storage system is found in industries that deal with food or perishables, or products that expire. The opposite of a FIFO system would be LIFO or “Last in First Out”.

Learn more about what the fifo storage method is, the differences and sililarities between a FIFO system and a LIFO system, and contact 3D Storage Systems with any questions.

Why do I frequently hear that “pushback is LIFO”?

When you look at an individual lane of pushback racking, pallets are loaded and unloaded from the same face. Therefore the first pallet put into a lane will be the last one out, and thus you have LIFO.

Rather than looking at how the entire pushback rack storage system is being used, many people just see the individual lane as LIFO and consider push back unsuitable for FIFO style storage.

So is pushback LIFO or FIFO?

A properly configured pushback system can achieve FIFO storage. The food industry is one of the largest users of FIFO pushback rack systems, and we all know that FIFO systems are crucial to their business.

The key to achieving a successful FIFO storage system is to have multiple lanes of the same product and to empty the oldest lanes first. This means that most users have medium to high volumes of each product to be stored – 5 or 6 pallets per SKU at a minimum.

We use the chart below to properly configure pushback FIFO systems.

| Number of pallets per product | Recommended lane depth for pushback |

| 1 – 4 | Use standard pallet rack |

| 5 – 8 | 2 Deep pushback |

| 9 – 12 | 2 – 3 Deep pushback |

| 13 – 16 | 3 – 4 Deep pushback |

| 17 – 20 | 4 – 5 Deep pushback |

| OVER 20 | 5 – 6 Deep pushback |

FIFO Storage In Action!

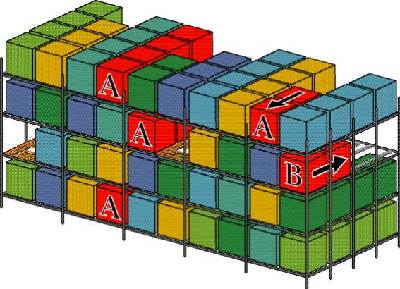

In the example shown below, we have a proper FIFO system with multiple lanes of “red” product. When new “red” product comes in we will put it in a new lane, even if there is a part lane of old “red” available. That way we never bury old products behind new ones. When it is time to ship we pick from the oldest lane first. This simple method ensures FIFO.

Choose 3D For Your FIFO System Configuration

Request a free FIFO systems quote or drawing or feel free to contact us for more information on our FIFO systems. We look forward to hearing from you!