In pushback systems, pallet orientation matters. Some operations have considered turning standard GMA pallets sideways to maximize layout options. On paper, it looks simple. In practice, it introduces handling and safety issues.

The Core Issue

GMA pallets are designed with fork entry on the 40-inch side. When you rotate them to load on the 48-inch face, the fork cut-outs offer minimal clearance. Standard lift truck forks are about the same height as the cut-outs and operators will struggle to align forks correctly, increasing the chance of errors.

What Happens When Pallets Are Turned Sideways

Fork tip protrusion – Because most standard forks are 42” long, the forks extend past the pallet being loaded, damaging product or the pallet behind.

Placement difficulties – fork tips catch on the load or pallet behind, making it hard to set pallets down properly.

Accidental double-picking – operators may lift the first pallet plus part of the second, pulling two pallets out of the lane unintentionally.

System damage – misaligned forks can strike cart cross-ties, bending or damaging the pushback structure.

Why Clients Ask for 48” Orientation

Even with the risks, some clients request sideways orientation. Here are some reasons why:

- Aisle space optimization: turning pallets can shorten lane depth, allowing tighter aisles or more rows.

- Building layout constraints: columns, doors, or conveyor equipment may force sideways alignment.

- Uniformity: clients may want consistent pallet orientation across all storage types.

- Load profile: rotating a pallet may keep an overhanging load within rack dimensions, or improve clearance for tall or fragile loads.

- Operator preference: some operators think sideways storage is easier, especially if they’ve used it in selective or bulk racking.

Real-World Lessons

Some operations require pallet orientation on the 48-inch face due to building layout or process flow. While this configuration introduces challenges, 3D has worked with clients to engineer effective solutions.

At Interamerican Foods, for example, a special design was developed to accommodate sideways orientation. By creating engineered fork pockets and addressing fork length considerations, the system was tailored to the client’s needs. Careful design and operator training ensured performance without compromising safety or efficiency.

The Engineering Fix

For some applications, 3D can create carts with dropped front ties that creates more clearance for the forks when picking up the pallet. This solution requires:

- Engineering adjustments to the rack design

- Lift trucks equipped with shorter forks (40”)

- Operator training to avoid damage during loading and unloading

- These fixes are viable but add cost and complexity.

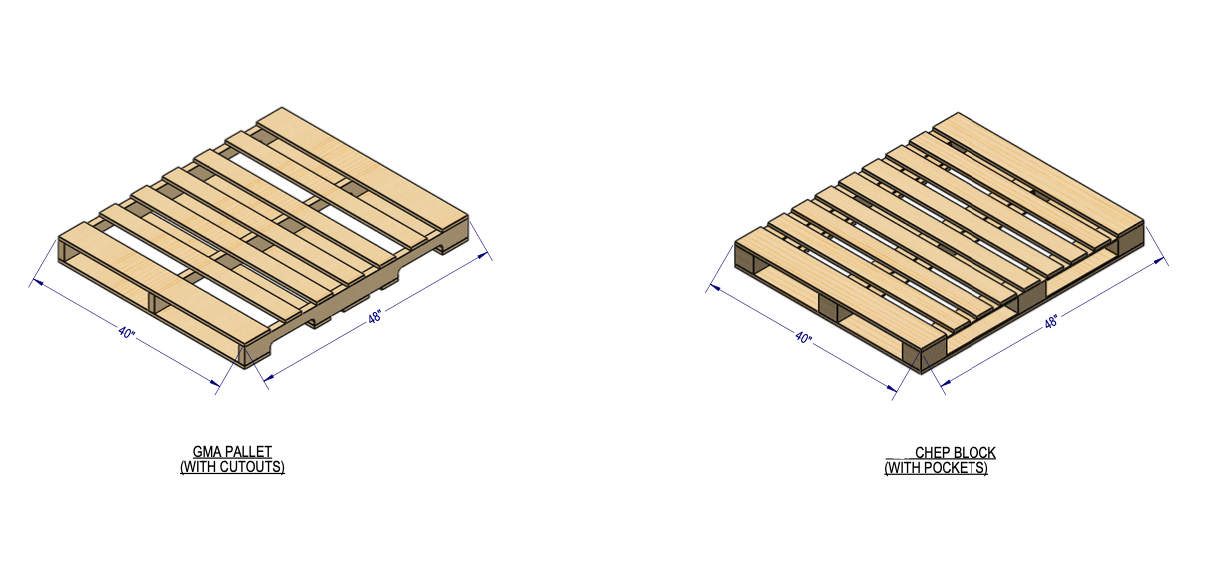

To make sideways orientation possible, we sometimes recommend different pallets be used. The diagram below highlights the difference: standard GMA pallets have shallow cut-outs, while block-style pallets like those supplied by CHEP allow for proper fork clearance and eliminates most of the issues discussed above.

Takeaway for Dealers and End Users

- Don’t assume pallets can be rotated in pushback lanes without consequences.

- Involve engineering early to assess pallet type, orientation, and truck compatibility.

- Protect your investment by ensuring the system is designed for the pallets you actually use.

If you’re evaluating pushback systems and want to ensure correct pallet orientation, talk to 3D Storage Systems. We’ll help you design it right the first time.